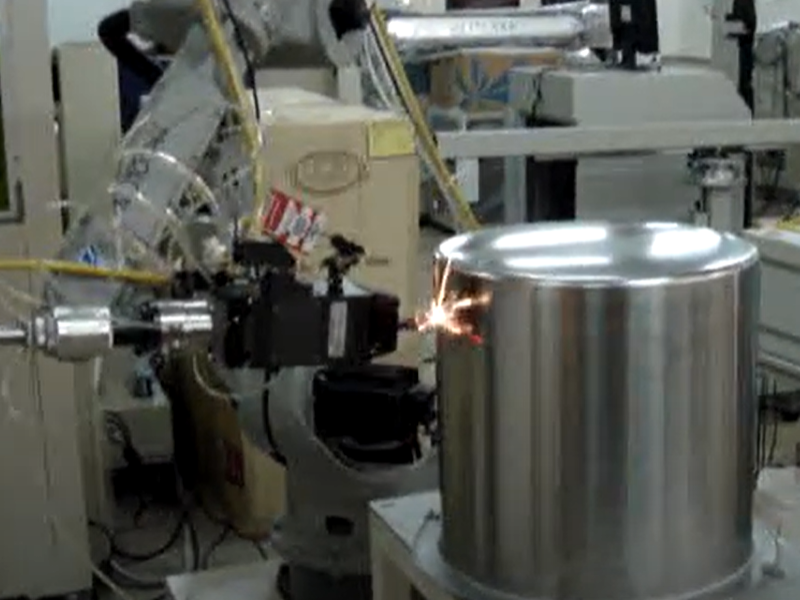

Description

Overview of robotic laser welding machine

Features of the robotic laser welding machine

- Seam Welding for Pot Bodies: They excel at joining cylindrical or curved pot side seams (e.g., stainless steel stock pots, saucepans). The robotic arm’s 6-axis flexibility ensures consistent laser focus along the entire curved or straight seam, creating strong, leakproof bonds with minimal heat distortion—critical for maintaining the pot’s structural integrity and smooth interior/exterior surfaces.

- Handle Attachment: Pot handles (whether metal, heat-resistant plastic, or a combination) require precise, durable welds to withstand repeated use and heat. Robotic systems program exact welding paths to secure handles to pot bodies, adjusting laser power to match handle and pot materials (e.g., aluminum handles on stainless steel pots) without damaging delicate components.

- Base Welding: For pots with detachable or integrated heat-diffusing bases (common in cookware for even heat distribution), the robotic laser welding machine delivers localized, high-precision welds. They can target small contact points between the pot body and base, ensuring firm adhesion while avoiding excessive heat that might warp the base or affect its thermal conductivity.

Advantages

- Custom and Decorative Welds: In premium or artisanal pot manufacturing, robotic laser welding accommodates intricate designs—such as decorative seams or logo embossing—by following pre-programmed patterns. This combines functionality with aesthetic appeal, enhancing product value without compromising weld strength.

- High-Volume Consistency: In mass production, the automation eliminates human error, ensuring every pot meets uniform quality standards. Robots operate continuously with minimal downtime, scaling efficiently to meet high production demands while reducing rework rates.

- Material-Specific Adaptability: Whether welding thin-gauge stainless steel for lightweight pots or thicker aluminum for Dutch ovens, the robotic laser welding machine adjusts laser parameters (power, pulse duration) to optimize fusion, preventing burn-through or weak joints.

These applications highlight how the technology balances precision, efficiency, and versatility, making it indispensable in modern pot manufacturing.

+8613906047998

+8613906047998