Description

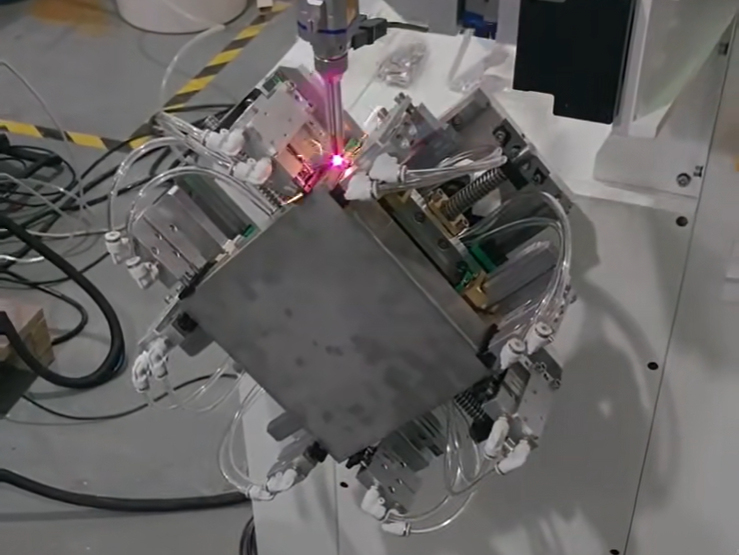

Customizable programmable laser welding machines are distinguished by their tailored functionality and advanced programmability, offering a blend of flexibility and precision.

Features

- Customization Capability: They can be tailored to specific industrial needs, including adjustable laser power, welding path configurations, and compatibility with diverse workpiece sizes or materials (such as metals, alloys, or delicate components).

- Programmable Precision: Equipped with intuitive software, they allow pre-set welding parameters (e.g., pulse duration, spot size) and automated path execution via CNC integration, ensuring consistent repeatability even for complex geometries.

- Adaptive Integration: Designed to sync with existing production lines, featuring modular interfaces for robotics, vision systems, or quality inspection tools, enhancing workflow efficiency.

Advantages

- Enhanced Versatility: Adapt seamlessly to small-batch prototypes or large-scale mass production, eliminating the need for multiple specialized machines.

- Superior Accuracy: Programmable controls minimize human error, delivering uniform welds with tight tolerances and reduced heat-affected zones, critical for high-precision industries like aerospace or electronics.

- Cost & Time Efficiency: Customized programming reduces setup times, while automated processes lower labor costs and boost throughput. Long-term, they adapt to evolving production demands, extending equipment lifespan.