Description

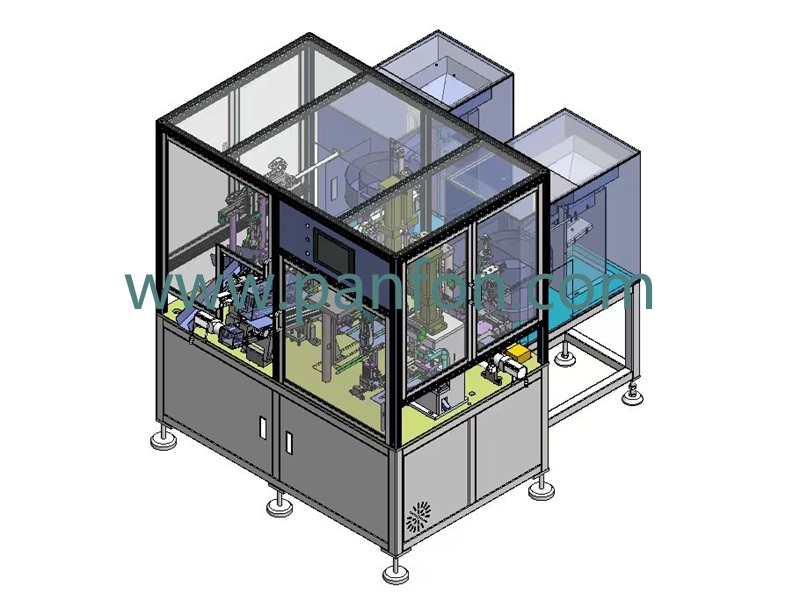

Custom perforated hose clamp assembly machine | full-automated

This automatic perforated hose clamp assembly machine can automatically completes the production process of Large Size Perforated American-type Hose Clamps from steel strip uncoiling, feeding, straightening, clamp housing automatic assembly, riveting, band curling/forming, screw/bolt-driving, testing, inspection to unloading.

Fully Automated | Perforated hose clamp assembly machine

American Type Stainless Steel Perforated hose clamp assembly machine is specialized automated systems designed for producing American-style hose clamps made from perforated stainless steel.

These machines integrate a sequence of precision processes tailored to the unique characteristics of this clamp type—including a stainless steel band with evenly spaced perforations (to engage the worm drive) and compliance with American dimensional standards.

Key functionalities include automated feeding of stainless steel strips, precision punching to create consistent perforations, die cutting to form the band’s length, and bending to achieve the required circular curvature. They also incorporate assembly modules that insert and secure the worm gear, ensuring seamless alignment with the perforations for reliable clamping force.

Equipped with adjustable tooling (to accommodate varying band widths, diameters, and perforation patterns) and programmable controls, these machines maintain strict material integrity (critical for stainless steel’s corrosion resistance) while streamlining high-volume production.

In-line quality checks—such as verifying perforation accuracy, gear alignment, and band strength—ensure compliance with industrial standards, making them ideal for manufacturing durable, precision-engineered American type perforated stainless steel hose clamps used in automotive, marine, and industrial fluid handling systems.

Workflow of Perforated hose clamp assembly machine:

- Step 1: The steel belt is fed accurately by servo motor, the length can be set, cut and formed by the mold.

- Step 2: The hoop shell is automatically loaded by the vibrating plate, assembled with the formed steel

strip and riveted. - Step 3: After completing the assembly of the product, the material is cut.

Specifications & Parameter

| Product name | Hose clamp assembly machine |

| Size | 1200mm(length)*1700mm(width)*1800(height) |

| Weight | 1Ton |

| Working area | 3000mm(length)*3000mm(width) |

| Strength | AC220v,50HZ |

| Pressure | 0.5Mpa-0.7Mpa(72.5-101.5PSI) |

| Efficiency | 1300pcs/hour |

| Service | One year |

+8613906047998

+8613906047998