Description

This Custom American Style Stainless Steel 304 hose clamp assembly machine, specialized for the first-stage processing and assembly of American-style 304 stainless steel hose clamps, is a precision-engineered system focusing on transforming raw stainless steel materials into partially finished clamps ready for final completion.

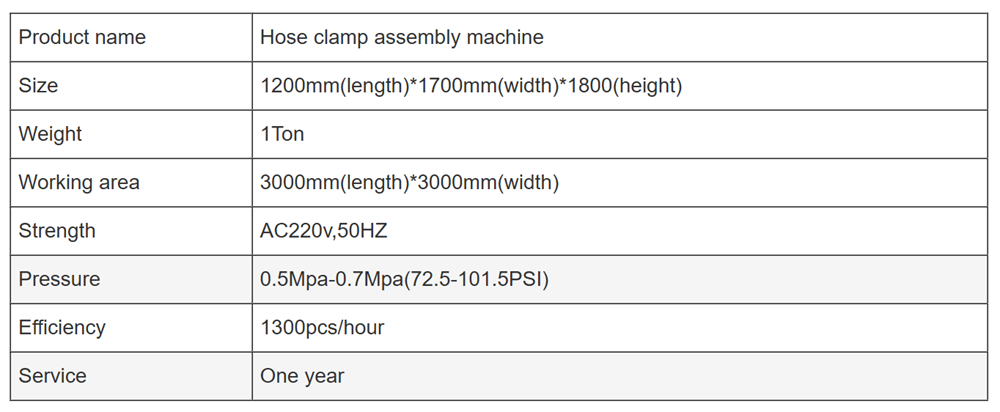

Stainless Steel 304 hose clamp assembly machine | American Style

In the processing phase, it handles key steps such as feeding stainless steel strips/bands, precision die cutting to achieve the required band length and width (adhering to American size standards), and forming/curling the band into a semi-circular or pre-curved shape.

A critical function here is creating the characteristic serrations or perforations along the band—essential for engaging the worm gear in the final clamp—using high-precision punching/press molding modules that ensure uniform spacing and alignment.

For the assembly portion of the first stage, the 304 hose clamp assembly machine integrates automated mechanisms to position and secure core components like the worm screw housing or initial gear structures onto the formed band. This step ensures proper alignment between the band’s serrations and the worm gear, laying the foundation for smooth clamping functionality in later stages.

Equipped with adjustable tooling to accommodate various band thicknesses and sizes (typical of American-type clamps), the SS hose clamp assembly machine maintains strict precision to preserve stainless steel’s corrosion resistance and structural integrity.

It streamlines the early manufacturing workflow, delivering consistent, partially assembled components that minimize manual intervention in subsequent production steps, making it ideal for high-volume manufacturing of durable American-style stainless steel hose clamps.

+8613906047998

+8613906047998