Description

German Type Hose Clamp Making Machine | Welding, band width 12mm

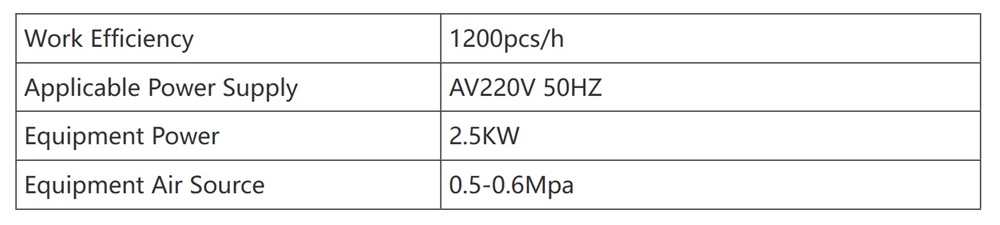

This Custom Automated Welding Solution Hose Clamp Making Machine is specialized, tailor-made systems engineered for the automated production of German-style hose clamps, with a defining feature: they utilize welding (rather than riveting) to secure the housing to the clamp band.

Automated Welding Assembly German Type Hose Clamp Making Machine

These machines integrate a sequence of precision processes tailored to German-type clamp specifications—known for their robust design, strict dimensional standards, and often higher clamping force requirements.

Key stages include automated feeding of stainless steel or high-grade metal strips, die cutting to form the band with precise serrations, and bending to achieve the characteristic circular shape.

The core distinction lies in the housing assembly phase: instead of traditional riveting, the machine employs advanced welding technologies (such as spot welding or laser welding) to permanently bond the housing—where the worm gear is housed—to the band.

This welding process ensures a stronger, more uniform joint, enhancing the clamp’s structural integrity and resistance to vibration or high-pressure environments, which aligns with the durability demands of German industrial standards.

Equipped with PLC controls, adjustable welding parameters, and in-line inspection systems (to verify weld strength and alignment), these machines maintain tight tolerances for German-type clamps of varying sizes.

They streamline the transition from raw materials to fully assembled clamps, reducing manual intervention, ensuring consistency, and catering to high-volume production needs in sectors like automotive, heavy machinery, and industrial fluid systems—where reliability and adherence to strict engineering standards are paramount.

+8613906047998

+8613906047998