Description

Tailored British-Style Hose Clamp Assembly Machine | High Speed

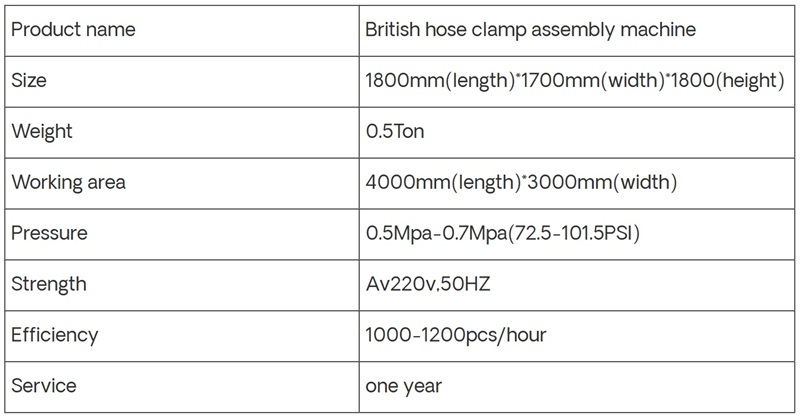

The High-speed British Hose Clamp Assembly Machine is designed and built for rapid, precision assembly of British-style hose clamps. It can be customized to meet specific production needs, making them adaptable to diverse manufacturing requirements.

British Hose Clamp Assembly Machine | High-Speed

Features of The High-speed British Hose Clamp Assembly Machine:

- High-Speed Performance: Engineered to handle fast-paced production lines, with rapid component feeding (clamp bands, screws, and British-standard housings) and seamless assembly cycles, significantly boosting output rates for mass production.

- British-Style Compatibility: Optimized for clamps adhering to British design specifications—typically featuring distinct band profiles, screw mechanisms, or sizing standards—ensuring accurate alignment and secure fitting of all components.

- Automated Precision: Integrates advanced sensors and robotic mechanisms to minimize errors in part placement, crimping, or fastening, maintaining consistent clamp tension and structural integrity critical for industrial, automotive, or plumbing applications.

- Flexibility: Adaptable to various British-style clamp sizes, with quick-change settings to accommodate diverse production needs, balancing speed with versatility. Ideal for high-volume manufacturing, it combines efficiency and precision to meet the demands of British-style hose clamp production.

Tailored-Customization of British Hose Clamp Assembly Machine :

- Component Compatibility: Adjustments to accommodate non-standard British-style clamp sizes, unique band thicknesses, or specialized hardware (e.g., custom screws, housings, or coating finishes) tailored to specific industry demands.

- Production Speed & Throughput: Calibration of cycle times, feeding mechanisms, or conveyor speeds to align with target output rates, whether scaling up for higher volumes or fine-tuning for precision-focused, medium-volume runs.

- Integration with Existing Lines: Modifications to interface with upstream/downstream equipment (e.g., automated feeding systems, quality inspection stations, or packaging lines) in existing production setups, ensuring seamless workflow integration.

- Specialized Features: Addition of custom sensors for defect detection, automated adjustment tools for variable clamp tension, or material-specific handling systems (e.g., for coated or treated steel bands) to address unique quality or material requirements.

We offer modular designs and configurable software/hardware components, allowing the machine to be tailored to specific production scales, clamp variations, or industry standards, ensuring it aligns closely with bespoke operational needs.

+8613906047998

+8613906047998