Description

Custom Automated Buzzer Assembly Machine-Rotary Indexing

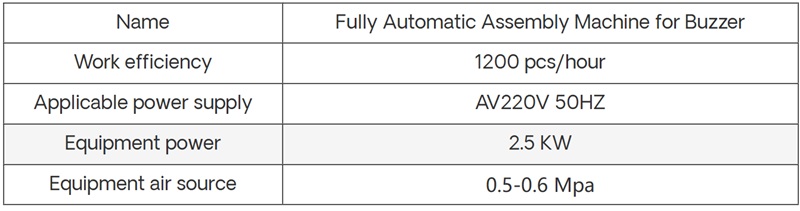

The Customized Automated Rotary Station solution for Buzzer Assembly Machine is a tailored automation system designed to streamline the assembly process of buzzers.

Automated Buzzer Assembly Machine Rotary Indexing Systems

At its core, this buzzer Assembly Machine solution features a rotary station—a rotating platform with multiple workstations arranged in a circular layout. This design enables continuous, sequential operations, maximizing efficiency by allowing different buzzer assembly steps to be performed simultaneously at each station.

Customization is key: the number of stations, their specific functions (such as part feeding, soldering, testing, or packaging), and the rotation speed can be adjusted based on the unique requirements of the buzzer being assembled (e.g., size, type, or production volume).

Integrated with automated components like robotic arms, conveyors, sensors, and control systems, the solution minimizes manual intervention, reduces errors, speeds up production, and ensures consistent quality—making it ideal for high-volume buzzer assembly.

FAQ 1. How does Rotary Indexing improve assembly efficiency?

The Automated Rotary Station solution enhances the buzzer assembly efficiency in several key ways, leveraging its design flexibility and automated capabilities:

Continuous, Parallel Operations

The rotary platform’s circular layout allows multiple workstations to perform distinct assembly steps (e.g., part feeding, soldering, testing, or sealing) simultaneously.

As one station completes its task, the platform rotates to move the workpiece to the next station—eliminating idle time between steps.

Tailored to Specific Needs

Customization ensures the number of stations, their functions, and rotation speed align precisely with the buzzer’s specifications (size, type) and production volume.

This optimization prevents bottlenecks and ensures resources are used efficiently.

Consistent Speed and Scalability

The system’s automated control ensures uniform rotation speed and step timing, maintaining a steady production rhythm.

For scaling, additional stations or faster rotation (within mechanical limits) can be easily incorporated into the customized design, allowing output to increase without major overhauls—supporting efficient growth in demand.

Real-Time Monitoring and Adjustment

Many solutions include smart control systems with sensors that track performance metrics (e.g., cycle time, error rates). This data enables quick adjustments (e.g., tweaking rotation speed or station timing) to address emerging bottlenecks, ensuring the line operates at peak efficiency and reducing unplanned downtime.

Together, these factors—parallel processing, tailored design, automation, consistency, and adaptability—combine to boost throughput, minimize waste, and enhance overall productivity in buzzer assembly.

+8613906047998

+8613906047998