Description

German hose clamp assembly machine | asymmetrical housing

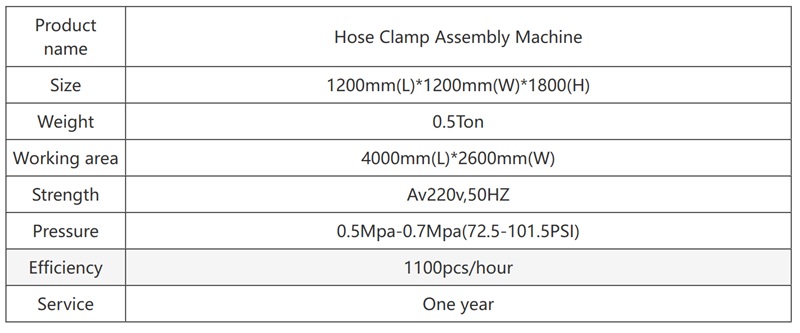

This customized machine for assembling Germany type asymmetrical/offset housing hose clamps, designed to automate the production process of such clamps, it typically features uneven or non-symmetrical housing structures to ensure precise assembly of components like the clamp band, housing, and screw mechanism. This is engineered for efficiency and accuracy in manufacturing, catering to industrial needs for secure hose connections.

Fully-automated German hose clamp assembly machine | asymmetrical housing

The German style asymmetrical housing German hose clamp assembly machine has some features include robust build quality, seamless integration of component alignment (clamp band, asymmetrical housing, and tightening hardware), and adjustable settings to accommodate varying clamp sizes, ensuring consistent assembly accuracy even for irregularly shaped parts.

A defining trait lies in its focus on asymmetrical housing design, which offers distinct advantages:

- Tailored Fit: The non-symmetrical housing contours to irregular or offset hose/pipe connections, ensuring a snugger grip in spaces where standard symmetrical clamps struggle to align—ideal for complex industrial setups with limited clearance.

- Enhanced Stability: By distributing pressure unevenly (concentrating force on critical contact points), it minimizes slippage or leakage in applications with varying diameter transitions or mismatched hose/pipe interfaces.

- Versatility: Adapts to diverse industrial needs, from automotive to heavy machinery, where non-standard hose layouts demand flexible clamping solutions without compromising seal integrity.

The machine leverages these housing properties to deliver reliable, production-ready clamps optimized for challenging installation environments.

+8613906047998

+8613906047998