Description

Hose clamp housing manufacturing machine | Fully-automated

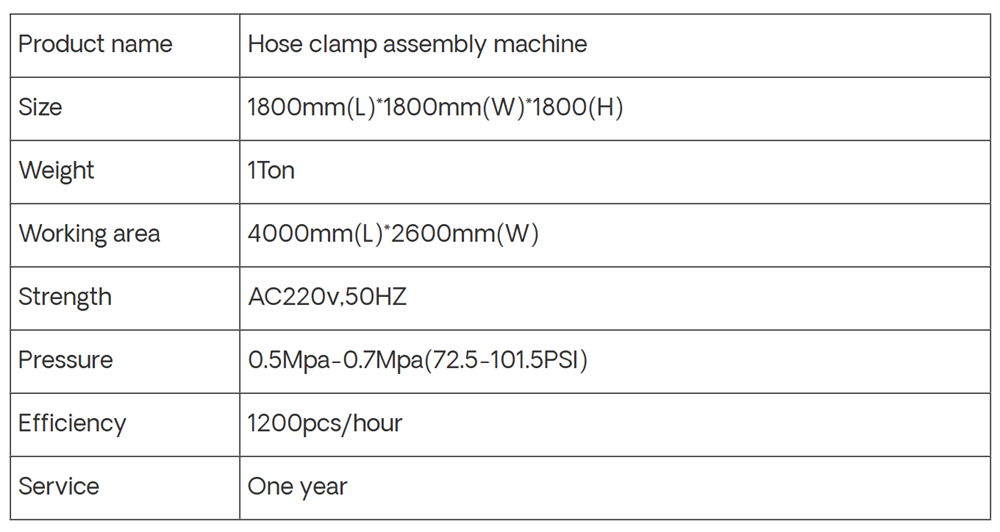

Hose clamp housing manufacturing machines are specialized automated systems designed for manufacturing the housing components of American-style hose clamps which are critical structural parts that encase and secure the worm gear, enabling the clamp’s adjustable clamping function.

Fully-automated American Style Hose clamp housing manufacturing machine

This Hose clamp housing manufacturing machine focuses on precision processing of metal materials (often stainless steel or galvanized steel) to form the housing’s distinct shape, which typically features a curved or U-shaped structure with integrated slots or cavities to accommodate the worm gear and band.

Key processes include automated material feeding, stamping or forging to shape the housing’s body, and precision machining (such as drilling or tapping) to create holes for gear rotation or band attachment.

Equipped with custom tooling tailored to American clamp standards—including specific dimensions, thicknesses, and gear engagement tolerances–they ensure consistency in housing geometry, which is vital for seamless integration with the clamp band and worm gear during final assembly. Many models also incorporate in-line quality checks (e.g., dimensional verification, structural integrity testing) to meet industrial durability requirements.

By automating housing production from raw metal blanks to finished components, the Hose clamp housing manufacturing machines enhance efficiency, reduce defects, and support high-volume output, making them essential in the manufacturing chain of American-style hose clamps used across automotive, plumbing, and industrial applications.

+8613906047998

+8613906047998