Description

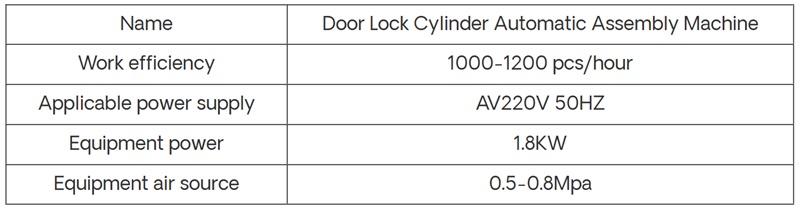

Custom Automated Lock Cylinder Assembly Machine

The Automated Lock Cylinder Assembly Machine is designed to assemble lock cylinder components (such as pins, springs, shells, and cores) with minimal manual intervention. It typically integrates feeding mechanisms (to supply parts), robotic or mechanical arms for precise handling, alignment tools, pressing/inserting modules, and quality inspection sensors.

Custom Automated Lock Cylinder Assembly Machine

The machine streamlines the assembly process by sequentially positioning and securing components—e.g., inserting pins into cores, fitting springs, and joining outer shells—ensuring consistency, accuracy, and high production efficiency.

It reduces human error, adapts to different lock cylinder specifications, and is widely used in lock manufacturing to meet mass production demands.

We customize Automated Lock Cylinder Assembly Machines tailored to specific lock cylinder types and production needs. Our systems integrate custom feeding mechanisms for diverse components (pins, springs, cores, shells), precision robotic handlers, and modular assembly stations.

They automate sequential tasks—part alignment, insertion, pressing, and locking—with adjustable parameters to adapt to varying cylinder sizes or designs.

Equipped with in-line inspection sensors, they detect misassemblies or defects in real time, ensuring consistency. We prioritize high throughput, minimal downtime, and user-friendly interfaces, delivering solutions that streamline mass production while reducing manual labor and errors.

+8613906047998

+8613906047998