Description

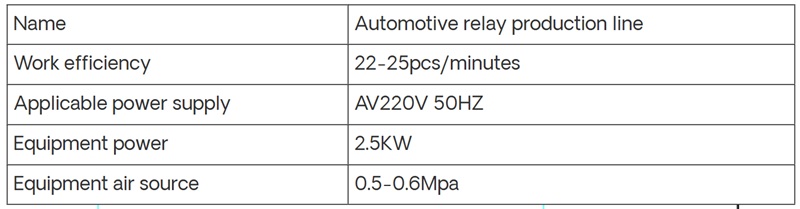

Automated Automotive Relay Assembly Production Line

An Automated Automotive Relay Assembly Line is a specialized production system designed to streamline the manufacturing of automotive relays—critical electrical components that control circuits in vehicles (e.g., for lights, motors, or safety systems).

Automated Automotive Relay Assembly Line

We offer an Automated Automotive Relay Assembly Line, a specialized production system tailored to streamline the manufacturing of automotive relays—vital electrical components that control circuits in vehicles, such as those for lights, motors, and safety systems.

Our assembly line integrates a sequence of automated stations to handle relay components (including coils, contacts, armatures, and plastic housings) through end-to-end assembly.

Key processes encompass automated part feeding via vibratory trays or robotic arms, precise alignment of components, robotic insertion of coils into bobbins, contact welding using techniques like resistance welding, assembly of magnetic cores, and housing sealing.

Equipped with advanced vision systems and sensors, our line conducts real-time quality checks—verifying component positioning, weld integrity, and electrical continuity—to ensure compliance with stringent automotive safety standards.

It may include both fully automated modules for high-volume production and semi-automated stations with minimal technician oversight, allowing for flexible adjustments.

By minimizing manual intervention, our Automated Automotive Relay Assembly Line achieves high precision, consistent quality, and fast throughput, effectively meeting the strict reliability and scalability demands of automotive manufacturing.

+8613906047998

+8613906047998