Description

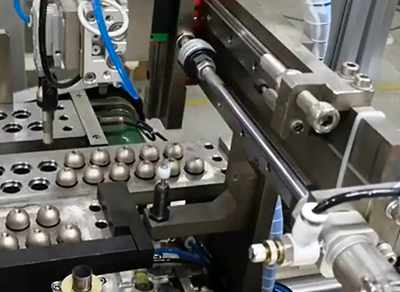

Custom tire valve assembly machine | Fully-automated

The fully automated tire valve assembly machine features high precision (ensuring tight component fit), high efficiency (fast cycle times for mass production), and full automation (reducing manual labor and errors). Its advantages include consistent product quality, easy integration into production lines, and adjustable settings for different valve stem specifications, enhancing overall manufacturing productivity.

Fully-automated tire valve assembly machine

We manufacture fully-automated tire valve assembly machines that streamline the entire production process of tire valves. Our machines integrate advanced technologies for automatic feeding of components such as valve bodies, stems, seals, and caps, ensuring precise positioning and seamless assembly.

Equipped with high-performance PLC systems, they operate with remarkable efficiency, significantly reducing manual intervention and minimizing the risk of errors. We’ve also incorporated real-time quality inspection modules to detect any defects during assembly, guaranteeing that each finished tire valve meets strict industry standards.

Designed with flexibility in mind, our tire valve assembly machines can be easily adjusted to accommodate different tire valve specifications, making them suitable for various production needs in the automotive tire parts industry. By choosing our fully-automated assembly machines, manufacturers can enhance production speed, improve product consistency, and ultimately boost their overall productivity.

+8613906047998

+8613906047998