On May 20 this year, CATL officially went public in Hong Kong, raising US$5.3 billion, becoming the world’s largest IPO this year.

This is not only a symbol of the prosperity of new energy, but also a huge opportunity for non-standard automation. As practitioners of non-standard automation, we see the trend of the next 10 years.

The coming golden decade of non-standard automation

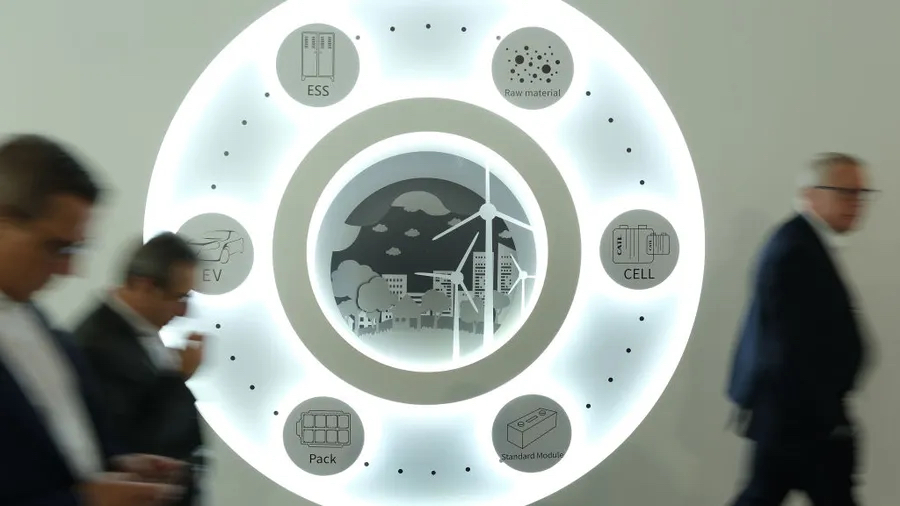

From battery cell manufacturing, PACK assembly to logistics handling, many of the key equipment used by CATL almost all belong to the category of non-standard automation – they are not standard products taken from the assembly line, but intelligent systems deeply customized according to the needs of the production line.

The “Invisible Force” Behind New Energy Giants: Non-Standard Automation

When expanding production, new energy giants like CATL, BYD, EVE Energy, and Tesla face the biggest challenge of rapidly building highly efficient and flexible production lines. This is where non-standard automation manufacturers come in.

Take CATL as an example:

- From raw material handling to front-end docking equipment for coating machines, they rely on custom automation systems to save manpower.

- Core processes like module assembly and laser welding require the coordinated use of high-precision, customized equipment.

- Data traceability and MES system integration are also the result of “custom integration” accomplished collaboratively by equipment engineers and software teams.

This also demonstrates that every expansion in the new energy industry drives billions of dollars in custom automation demand.

CATL is driving not just batteries, but the entire supply chain.

Following its Hong Kong IPO, CATL has explicitly stated its commitment to strengthening its localized manufacturing capabilities globally.

This means that more overseas battery factories will be established in the next two to three years. This presents two key development opportunities for Chinese non-standard automation manufacturers:

- New dividends from “going global”: Providing complete line solutions for overseas new energy factories, particularly battery manufacturing, packaging, and end-of-life testing lines, allows technically mature non-standard manufacturers to tap into the international market.

- Strong demand from domestic supporting manufacturers: CATL’s production expansion often drives simultaneous expansion of its upstream and downstream operations, including battery casing and tab welding, liquid injection, and airtightness testing. Demand for non-standard equipment is growing exponentially.

What should customized equipment manufacturers focus on?

For companies operating in the non-standard customized automation industry, CATL’s IPO signals the following:

The wave of high-end manufacturing is approaching, and the next stage of growth will hinge not on price but on technology and customization capabilities.

- Engineers should enhance their interdisciplinary capabilities: mechanics, electronics, vision, and software. The stronger their integration capabilities, the more likely they are to participate in core projects.

- Companies should accelerate system upgrades: Non-standard projects are not just about building a single piece of equipment, but about providing flexible solutions for entire production lines.

- Focus on international market compliance and standards: Serving overseas customers will become the norm in the future, and technicians who understand IEC standards, local safety regulations, and are skilled in communication will be the new favorites.

Despite the boom in lithium-ion batteries, talent has become a major drawback.

In 2024 alone, the number of new jobs in the lithium-ion battery equipment industry increased by over 47% year-on-year. However, designers capable of designing custom equipment, with expertise in structure, motors, and controls, are in severe short supply.

From electrode coating to module assembly, from laser welding to pack production lines, every process relies heavily on custom automation equipment. These devices aren’t simply “one-click orders” from online retailers; they are deeply customized, designed, and debugged by engineers.

As CATL expands its production lines both domestically and internationally, market demand for the following equipment is booming:

- Electrode alignment and loading devices

- Flexible conveying systems for module and pack lines

- Automatic laser welding and CCD vision positioning systems

- Specialized process equipment for cell filling and airtightness testing.

These all fall under the category of custom automation equipment, and each piece of equipment requires the support of one to three skilled designers.

Many corporate clients are not looking for technical expertise when hiring, but rather engineers who truly understand the equipment’s logic, can quickly generate drawings, and can directly engage in debugging.

+8613906047998

+8613906047998